|

|

|

|

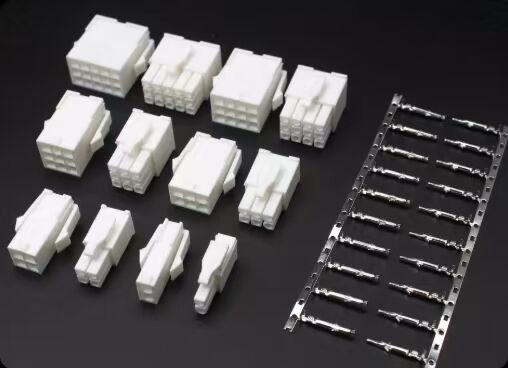

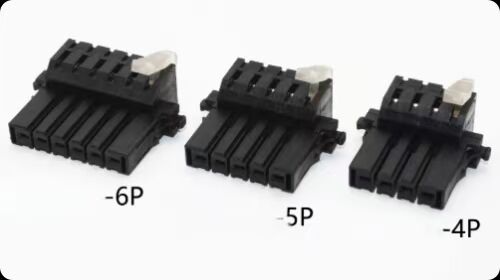

Applicable Panasonic servo driver plugs A5/A6 connector XA/XB/X2/X4/X6 encoder motor plugs

|

제품 상세 정보:

결제 및 배송 조건:

|

| 이름: | Moog ITT 커넥터 | 연락처 수: | Omrons 국내 |

|---|---|---|---|

| 어플리케이션: | 산업 자동화 | 종료 유형: | 압착/납땜 |

| 와이어 게이지: | 18-24 AWG 이상 AWG 3-12 직경 | 전압 정격: | 1000V |

| 현재 등급: | 배터리 | 작동 온도: | -40 +~ +105 ℃ |

| 강조하다: | Panasonic servo driver plugs,A5 A6 connector plugs,XA XB X2 X4 X6 encoder motor plugs |

||

Applicable Panasonic servo driver plugs A5/A6 connector XA/XB/X2/X4/X6 encoder motor plugs

![]()

![]()

![]()

![]()

Product Description:

The Moog ITT Connector is a high-performance servo motor connector specifically designed to meet the rigorous demands of modern industrial applications. Engineered with precision and durability in mind, this connector is an essential component for a wide range of servo motor systems, including AC Servo Motor Drivers, AC Brushless Servo Motors, and Electro Hydraulic Servo setups. With its robust construction and reliable performance, the Moog ITT Connector ensures seamless electrical connectivity and efficient power transmission in critical control environments.

One of the standout features of the Moog ITT Connector is its impressive voltage rating of 1000V, which guarantees safe and stable operation even under high-voltage conditions. This high voltage tolerance makes it an ideal choice for advanced servo systems, where maintaining consistent electrical integrity is crucial for optimal motor performance. Whether used in precision motion control applications or heavy-duty industrial machinery, this connector provides the reliability and safety that engineers and technicians demand.

The Moog ITT Connector is designed with a gender specification that aligns perfectly with Moog components, ensuring compatibility and ease of integration within Moog servo motor assemblies. This gender specification simplifies the assembly process, reducing installation time and minimizing the risk of connection errors. Its versatile design supports wire gauges ranging from 18 to 24 AWG, as well as larger diameters from AWG 3 to 12, making it adaptable to various cable types and sizes commonly used in servo motor installations. This flexibility allows for a wide range of application possibilities, from small-scale servo controllers to large electro hydraulic servo systems.

Temperature resilience is another critical aspect of the Moog ITT Connector, which is rated to operate efficiently within a broad temperature range of -40℃ to +105℃. This wide operating temperature range ensures that the connector can withstand harsh environmental conditions, including extreme cold and heat, without compromising its performance or structural integrity. Such temperature tolerance is especially important in industrial settings where equipment may be exposed to fluctuating temperatures, ensuring continuous operation and reducing downtime caused by connector failures.

In applications involving AC Servo Motor Drivers and AC Brushless Servo Motors, the Moog ITT Connector delivers exceptional electrical contact and mechanical stability. Its design minimizes signal loss and electrical noise, which are critical factors in achieving precise motor control and smooth operation. This reliability extends to Electro Hydraulic Servo systems as well, where consistent electrical connectivity is vital for accurate hydraulic control and system responsiveness.

Durability and longevity are at the core of the Moog ITT Connector’s design philosophy. Manufactured from high-quality materials, it offers excellent resistance to corrosion, vibration, and mechanical stress. This makes it suitable for use in demanding industrial environments, including manufacturing plants, automation systems, robotics, and heavy machinery. The connector’s robust construction helps reduce maintenance costs and ensures consistent system uptime, contributing to overall operational efficiency.

In summary, the Moog ITT Connector stands out as a premium solution for servo motor connectivity, combining high voltage rating, flexible wire gauge compatibility, and exceptional temperature tolerance. Its compatibility with Moog components, along with its suitability for AC Servo Motor Drivers, AC Brushless Servo Motors, and Electro Hydraulic Servo applications, makes it a versatile and reliable choice for engineers and technicians seeking dependable performance in their servo motor systems. By choosing the Moog ITT Connector, users can expect enhanced electrical performance, increased operational reliability, and a connector that meets the stringent demands of modern industrial servo applications.

Features:

- Product Name: Servo Motor Connectors

- Insulation Resistance: 10PIN

- Voltage Rating: 1000V

- Material: Metal/Plastic

- Application: Industrial Automation

- Connector Type: Servo Motor

- Compatible with AC Servo Drive systems

- Ideal for use with AC Servo Motor Driver setups

- Supports DC Servo Motor Drive connections

Technical Parameters:

| Voltage Rating | 1000V |

| Connector Type | Servo Motor |

| Contact Plating | Silver Pin, Golded Pin |

| Mounting Type | Panel Mount / Cable Mount |

| Material | Metal / Plastic |

| Operating Temperature | -40℃ To +105℃ |

| Name | Moog ITT Connector |

| Wire Gauge | 18-24 AWG Or More, AWG 3-12 Diameter |

| Current Rating | Battery |

| Insulation Resistance | 10PIN |

Applications:

The NO MARK servo motor connector, model number servo motor connector, is a high-quality product originating from China, designed specifically for seamless integration with AC Brushless Servo Motor systems and DC Servo Motor Drive applications. Certified with CE and ISO9001 standards, this connector guarantees reliable performance and adherence to international quality requirements, making it an ideal choice for industrial automation and precision motion control scenarios.

Featuring a 10PIN insulation resistance design, the NO MARK servo motor connector ensures secure and stable electrical connections, essential for the demanding environments where AC Brushless Servo Motors operate. Its current rating is suitable for battery-powered systems, providing efficient power transmission and minimizing signal loss. The connector’s versatility is further enhanced by its dual mounting types—Panel Mount and Cable Mount—allowing it to be easily installed in various equipment configurations and facilitating flexible system designs.

In practical applications, this servo motor connector is widely used in robotics, CNC machinery, automated production lines, and other industrial equipment that rely on precise motor control. The connector’s robust construction and reliable contacts make it perfect for continuous operation within AC Brushless Servo Motor drives, ensuring consistent torque and speed control. Additionally, it supports DC Servo Motor Drive systems, where accurate and responsive motor management is crucial for performance and efficiency.

Manufactured under the reputable Moog ITT Connector name, the product is packaged securely in carton boxes to prevent damage during transit. With a supply ability of 1000 pieces per day and a minimum order quantity of 100, the NO MARK servo motor connector supports both large-scale production and smaller batch requirements. Delivery is prompt, typically within 1-3 working days, and payment can be conveniently made via T/T or PayPal, supporting a smooth procurement process.

Overall, the NO MARK servo motor connector is a dependable component designed to meet the rigorous demands of modern servo motor applications. Its compatibility with AC Brushless Servo Motor and DC Servo Motor Drive systems, combined with certified quality and flexible mounting options, makes it an indispensable part for engineers and manufacturers seeking reliable connectivity solutions in the field of advanced motor control.

Customization:

Our Servo Motor Connectors, branded as NO MARK and model number servo motor connector, are designed to meet the demanding needs of Electro Hydraulic Servo systems, Hydraulic Brake Motors, and AC Servo Drive applications. Manufactured in China and certified with CE and ISO9001, these connectors ensure reliable performance and quality.

We offer product customization services to accommodate specific requirements such as voltage rating up to 1000V, wire gauge options from 18-24 AWG or more, and AWG 3-12 diameter configurations. The connectors feature 10PIN insulation resistance and are compatible with Moog ITT Connector standards, supporting current ratings suitable for Battery applications.

Our minimum order quantity is 100 pieces, with a supply ability of 1000 pcs/day, ensuring prompt availability. Packaging is done in sturdy carton boxes to protect the product during transit. Delivery time is typically 1-3 working days after order confirmation.

We accept flexible payment terms including T/T and PayPal to facilitate smooth transactions. Whether you require connectors for Electro Hydraulic Servo units, Hydraulic Brake Motors, or AC Servo Drive systems, our customization services are tailored to meet your exact specifications and quality standards.

Support and Services:

Our Servo Motor Connectors are designed to provide reliable and secure connections for servo motor applications, ensuring optimal performance and durability. These connectors are engineered to withstand harsh industrial environments and deliver consistent electrical conductivity.

Technical support for our Servo Motor Connectors includes assistance with product selection, installation guidance, troubleshooting, and maintenance tips. Our experts are available to help you identify the right connector specifications based on your servo motor requirements and system configurations.

We offer comprehensive services such as custom connector solutions, compatibility assessments, and lifecycle management to support your operational needs. Additionally, we provide detailed product documentation, including datasheets, wiring diagrams, and installation manuals to facilitate seamless integration.

For ongoing support, we recommend regular inspection and cleaning of connectors to prevent contamination and ensure secure connections. Should you encounter any issues, our technical team can assist with diagnostics and recommend appropriate corrective actions to minimize downtime.

Our commitment is to deliver high-quality Servo Motor Connectors backed by expert technical support and tailored services, helping you achieve maximum efficiency and reliability in your servo motor systems.

담당자: Zhou

전화 번호: +8613316962478