|

|

|

|

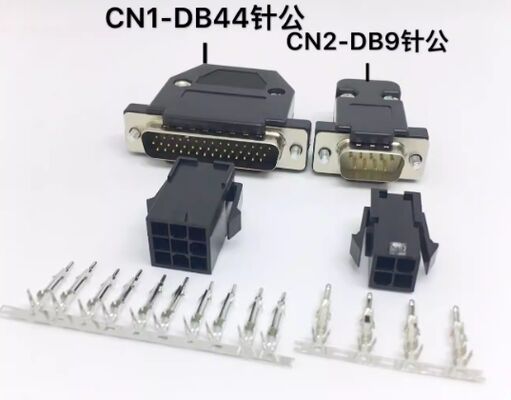

Applicable to Delta AB/B2/B3/A2/A3 servo drives CN1 connector for encoder, CN2 plug for motor

|

제품 상세 정보:

결제 및 배송 조건:

|

| 재료: | 금속/플라스틱 | 커넥터 유형: | 서보 모터 |

|---|---|---|---|

| 애플리케이션: | 산업 자동화 | 종료 유형: | 압착/납땜 |

| 접촉 도금: | 은색 핀 금박 핀 | 연락처 수: | 오므론스 국내 |

| 성별: | 무그 | 작동 온도: | -40℃에 +105℃ |

Applicable to Delta AB/B2/B3/A2/A3 servo drives CN1 connector for encoder, CN2 plug for motor

![]()

![]()

Product Description:

The Servo Motor Connectors are precision-engineered components designed to ensure reliable and efficient connections in a variety of servo motor applications. These connectors are specifically compatible with DC Servo Motor Drive systems, AC Servo Motor Driver units, and Hydraulic Brake Motors, making them versatile choices for many industrial and automation environments. Their robust construction and superior electrical performance make them ideal for demanding applications where consistent power delivery and signal integrity are critical.

One of the standout features of these Servo Motor Connectors is their compatibility with a wide range of wire gauges, accommodating 18-24 AWG or larger wires with diameters ranging from 3 to 12 AWG. This flexibility allows for easy integration with different motor setups, enabling users to select the appropriate wire size to handle varying current loads and mechanical stresses. Whether you are working with small control signals or higher power connections, these connectors provide the necessary adaptability to suit your specific requirements.

The termination type of these connectors includes both crimp and solder options, offering versatility in installation methods. Crimp terminations provide quick, secure connections that are resistant to vibration and mechanical strain, which is essential in dynamic environments such as those involving Hydraulic Brake Motors. On the other hand, solder terminations ensure a permanent, low-resistance connection that enhances electrical conductivity and long-term reliability. This dual termination capability allows technicians and engineers the freedom to choose the most suitable method based on the application and environmental conditions.

In terms of electrical performance, these Servo Motor Connectors are rated to handle battery current levels effectively, ensuring that they can support the power demands of both DC Servo Motor Drive and AC Servo Motor Driver systems. Their design ensures minimal power loss and heat generation, contributing to the overall efficiency and longevity of the motor control system. Reliable current handling is crucial in servo motor applications where precise control and consistent torque delivery are necessary for optimal performance.

Operating temperature range is another critical aspect where these connectors excel. They are engineered to function reliably in harsh environments, with an operating temperature range from -40℃ to +105℃. This wide temperature tolerance ensures stable performance in extreme conditions, whether in cold storage facilities, outdoor installations, or high-temperature industrial zones. Such resilience makes these connectors particularly suitable for demanding applications involving Hydraulic Brake Motors, where temperature fluctuations are common due to mechanical braking heat and ambient conditions.

Mounting versatility is also a key characteristic of these Servo Motor Connectors. They are designed for both panel mount and cable mount configurations, providing flexibility in how they are integrated into motor control systems. Panel mount options allow for secure attachment to control panels or enclosures, facilitating organized wiring and easy maintenance access. Cable mount variants offer the advantage of direct connection to motor cables, simplifying the wiring process and reducing installation time. This adaptability ensures that the connectors can be seamlessly incorporated into various system designs and layouts.

In summary, the Servo Motor Connectors combine robust mechanical design, excellent electrical characteristics, and versatile installation options to meet the stringent demands of modern servo motor applications. Their compatibility with DC Servo Motor Drive and AC Servo Motor Driver systems, as well as Hydraulic Brake Motors, underscores their utility across a broad spectrum of industrial and automation applications. With wire gauge support from 18-24 AWG or more, crimp and solder termination types, battery current rating, wide operating temperature range from -40℃ to +105℃, and flexible panel or cable mounting options, these connectors provide a comprehensive solution for ensuring reliable, efficient, and durable connections in servo motor systems.

Features:

- Product Name: Servo Motor Connectors

- Connector Type: Moog ITT Connector

- Operating Temperature Range: -40℃ to +105℃

- Current Rating: Battery compatible

- Mounting Type: Panel Mount and Cable Mount options available

- Insulation Resistance: 10 PIN configuration

- Compatible with AC Servo Drive systems

- Suitable for DC Servo Motor Drive applications

- Ideal for use with Hydraulic Brake Motors

Technical Parameters:

| Operating Temperature | -40℃ To +105℃ |

| Connector Type | Servo Motor |

| Gender | Moog |

| Voltage Rating | 1000V |

| Name | Moog ITT Connector |

| Insulation Resistance | 10PIN |

| Contact Plating | Silver Pin, Golded Pin |

| Termination Type | Crimp/Solder |

| Current Rating | Battery |

| Mounting Type | Panel Mount/Cable Mount |

Applications:

The NO MARK servo motor connector, model number servo motor connector, is a high-quality product originating from China, designed to meet the diverse needs of industrial and automation applications. Certified by CE and ISO9001, this connector guarantees reliable performance and compliance with international standards. Its robust construction and superior materials, such as silver-plated and gold-plated pins, ensure excellent conductivity and durability, making it an ideal choice for connecting AC brushless servo motors and electro hydraulic servo systems.

This servo motor connector is specifically engineered to operate efficiently within a wide temperature range of -40℃ to +105℃, allowing it to perform reliably in harsh and demanding environments. With a 10-pin configuration and insulation resistance optimized for safety and signal integrity, it supports seamless communication and power transmission between servo motor components. The connector type is tailored for servo motor applications, ensuring compatibility with Omrons domestic contacts and other high-precision equipment.

Typical application occasions for the NO MARK servo motor connector include automated manufacturing lines, robotics, CNC machinery, and electro hydraulic servo systems used in various industrial sectors. It plays a critical role in ensuring stable electrical connections in AC brushless servo motor setups, which are commonly found in precision motion control and automation projects. Additionally, this connector is extensively used in electro hydraulic servo applications, where precise control of hydraulic actuators is essential for machine efficiency and accuracy.

The product is available for order with a minimum quantity of 100 pieces, packaged securely in carton boxes to prevent damage during transit. NO MARK offers a supply ability of 1000 pieces per day, ensuring prompt availability for large-scale production needs. Delivery is fast, typically within 1-3 working days, and payment options include T/T and PayPal for convenient transactions.

In summary, the NO MARK servo motor connector is a dependable and versatile component ideal for various servo motor and electro hydraulic servo applications. Its quality certifications, robust design, and quick delivery make it a preferred choice for engineers and manufacturers seeking efficient and reliable connection solutions in the field of motion control and automation technology.

Customization:

Our servo motor connectors, branded as NO MARK and model number servo motor connector, are designed to meet the highest standards of quality and performance. Originating from China, these connectors are certified with CE and ISO9001, ensuring reliability and safety in industrial automation applications. With a minimum order quantity of 100 units, we cater to both small and large scale requirements.

The Moog ITT Connector for servo motors supports panel mount and cable mount installation types and features a number of contacts compatible with Omrons Domestic standards. Our connectors are suitable for use with Hydraulic Brake Motors and AC Servo Drive systems, providing robust and efficient connections for your industrial automation needs.

We package each order securely in carton boxes, ensuring safe delivery within 1-3 working days. Our supply ability reaches up to 1000 pieces per day, allowing us to fulfill orders promptly. Payment terms include T/T and PayPal for your convenience.

Current ratings are optimized for battery applications, making these connectors versatile and reliable. Whether you are integrating with Hydraulic Brake Motors or configuring an AC Servo Drive, our servo motor connectors offer the performance and durability required for demanding industrial environments.

Support and Services:

Our Servo Motor Connectors are designed to provide reliable and secure connections for servo motor systems, ensuring optimal performance and durability in various industrial applications.

Technical support is available to assist with product selection, installation guidance, troubleshooting, and maintenance tips to maximize the lifespan and efficiency of your servo motor connectors.

We offer comprehensive services including connector customization, compatibility verification with different servo motor models, and advice on proper wiring techniques to prevent common issues such as signal loss or interference.

For any technical inquiries or support needs, our team of experts is ready to provide prompt and detailed assistance to ensure seamless integration of the servo motor connectors in your systems.

Additionally, we provide detailed product documentation, including datasheets, wiring diagrams, and installation manuals, to support your technical requirements and facilitate easy installation and operation.

담당자: Zhou

전화 번호: +8613316962478